- Kenmore refrigerator water filters

- Whirlpool refrigerator water filters

- Samsung refrigerator water filters

- GE refrigerator water filters

- LG refrigerator water filters

- Frigidaire refrigerator water filters

- KitchenAid refrigerator water filters

- Maytag refrigerator water filters

- Kenmore Elite refrigerator water filters

- Estate refrigerator water filters

- GE Profile refrigerator water filters

- Amana refrigerator water filters

- Bosch refrigerator water filters

- Dacor refrigerator water filters

- Electrolux refrigerator water filters

How to rebuild an air compressor pump

This DIY repair guide explains how to rebuild the pump on an air compressor. The air compressor motor drives a piston that compresses air in the pump cylinder to fill the compressor tank. Worn pump parts— such as the valve plate and seals—stop the pump from compressing the air and filling the tank. Rebuilding the air compressor pump restores the pump's ability to efficiently compress air.

If the tank won't build pressure because the pump seals or valve plate are worn, rebuild the pump using the manufacturer-approved air compressor parts. Most air compressor models use a kit for rebuilding the air compressor pump. The rebuild kit includes the cylinder sleeve, piston and seals.

Follow the steps in this repair guide and video to install the air compressor pump rebuild kit on Craftsman, Porter Cable, DeWalt and Devilbiss air compressors.

Quick links

Video

Instructions

Tools required

Work gloves

Slot screwdriver

T-15 Torx driver

Torque wrench

Wrench set

Repair difficulty

Time required

45 minutes or less

Repair difficulty

Time required

45 minutes or less

Rebuilding a pump in an air compressor

This video explains how to rebuild the pump on an air compressor.

Instructions

- 01.

Shut off the electricity and drain the air tank

Unplug the air compressor’s power cord from the wall outlet.

Pull the ring on the safety valve to drain all air pressure from the tank. Wear work gloves to protect your hands.

PHOTO: Unplug the power cord.

PHOTO: Drain the air tank.

- 02.

Remove the compressor shroud

Remove the shroud mounting screws.

Using a slot tip screwdriver, pry the shroud halves apart at the locking tabs and remove the shroud.

PHOTO: Remove the shroud mounting screws.

PHOTO: Pry the shroud halves apart.

- 03.

Disassemble the pump head

Remove the air outlet tube from the pump head.

Remove the mounting bolts from the pump head and lift the head off the pump.

Lift the valve plate off the pump.

PHOTO: Disconnect the air outlet tube.

PHOTO: Remove the pump head bolts.

PHOTO: Remove the pump head.

PHOTO: Remove the valve plate.

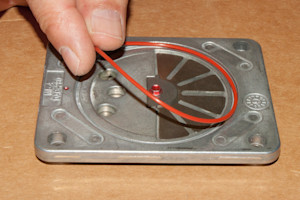

- 04.

Remove the fan

Remove the fan mounting bolt and pull the fan off.

PHOTO: Remove the fan mounting bolt and the fan.

- 05.

Remove the piston and sleeve

Loosen the Torx screw that clamps the piston connecting rod to the eccentric bearing. Pull the connecting rod off the eccentric bearing.

Push the piston and cylinder sleeve up and out of the pump body. Push the piston out of the cylinder sleeve.

PHOTO: Loosen the Torx screw.

PHOTO: Pull the connecting rod off the bearing.

PHOTO: Push the piston and sleeve up and out of the pump body.

PHOTO: Push the piston out of the sleeve.

- 06.

Remove the compression ring

Remove the Torx screw from the top of piston.

Remove the piston cap and compression ring.

PHOTO: Remove the Torx screw.

PHOTO: Remove the piston cap and compression ring.

- 07.

Install the new compression ring

Place the new compression ring on the top of the piston.

Reinstall the piston cap and Torx screw.

PHOTO: Install the new compression ring.

PHOTO: Reinstall the piston cap and Torx screw.

- 08.

Install the new cylinder sleeve

Slide the piston into the new cylinder sleeve.

Insert the piston and cylinder sleeve into the pump body.

PHOTO: Slide the piston down into the sleeve.

PHOTO: Insert the piston and cylinder sleeve into the pump.

- 09.

Reinstall the piston

Push the piston connecting rod onto the eccentric bearing.

Align the piston connecting rod flush with the eccentric bearing.

Tighten the piston connecting rod Torx screw to 48 inch-pounds using a torque wrench.

PHOTO: Push the connecting rod onto the bearing.

PHOTO: Tighten the Torx screw.

- 10.

Reinstall the fan

Push the fan onto the keyed shaft.

Reinstall the fan mounting bolt.

Tighten the fan mounting bolt to 120 inch-pounds.

PHOTO: Push the fan onto the shaft.

PHOTO: Install the bolt and tighten.

- 11.

Install the new valve plate

Press the new valve plate seals into the seal channels on the new valve plate.

Place the new valve plate on the pump body with the reed valves positioned on the handle side of the air compressor.

PHOTO: Install the new upper valve plate seal.

PHOTO: Install the new lower valve plate seal.

PHOTO: Place the valve plate on the pump.

- 12.

Reinstall the pump head

Position the pump head over the new valve plate with the muffler side of the pump head over the reed valves on the valve plate.

Reinstall the pump head mounting bolts.

Tighten the pump head mounting bolts to 7 foot-pounds.

Reinstall the outlet tube on the pump head.

PHOTO: Place the head over the valve plate.

PHOTO: Install the pump head bolts and tighten.

PHOTO: Reinstall the outlet tube to the pump head and tighten.

- 13.

Reinstall the shroud

Position the large half of the shroud over the compressor and install the back screw.

Slide the smaller half of the shroud into the large half of the shroud and engage the shroud locking tabs.

Reinstall the front mounting screws in the shroud.

PHOTO: Install the large shroud.

PHOTO: Install and tighten the back screw.

PHOTO: Install the small shroud and tighten the screws.

- 14.

Restore power

Plug the air compressor into the electrical outlet.

PHOTO: Plug the compressor in.

Warning: Undertaking repairs to appliances can be hazardous. Use the proper tools and safety equipment noted in the guide and follow all instructions. Do not proceed until you are confident that you understand all of the steps and are capable of completing the repair. Some repairs should only be performed by a qualified technician.

Most common symptoms to help you fix your air compressors

Choose a symptom to see related air compressor repairs.

Main causes: loose air tube fitting connections, bad check valve, faulty safety valve, damaged or corroded air tank, bad…

Main cause: bad check valve…

Main causes: tank drain valve open or leaking air, leaky air tank, bad safety valve, worn pump seals, bad pump valve pla…

Main causes: rusted air tank, loose air tube fitting connections, bad check valve, leaky safety valve, bad tank drain va…

Main causes: bad safety valve, pressure switch failure…

Main cause: faulty output air pressure regulator…

Main cause: bad air tank pressure gauge…

Main causes: lack of electrical power, check valve failure, bad pressure switch…

Most common repair guides to help fix your air compressors

These step-by-step repair guides will help you safely fix what’s broken on your air compressor.

How to replace an air compressor pressure switch

You can replace a broken air compressor pressure switch in about 45 minutes. …

Repair difficulty

Time required

45 minutes or less

How to rebuild an air compressor pump

If the air compressor won't fill the tank with compressed air, rebuild the pump using these steps in about 45 minutes. …

Repair difficulty

Time required

45 minutes or less

How to replace an air compressor check valve

You can replace a defective air compressor check valve in about 10 minutes.…

Repair difficulty

Time required

15 minutes or less

Effective articles & videos to help repair your air compressors

Use the advice and tips in these articles and videos to get the most out of your air compressor.

Learn how to tell whether a fuse is blown…

Find out how to reduce air compressor noise.…

See how to perform routine maintenance on your oil-lubricated air compressor.…